Robots learn human movements

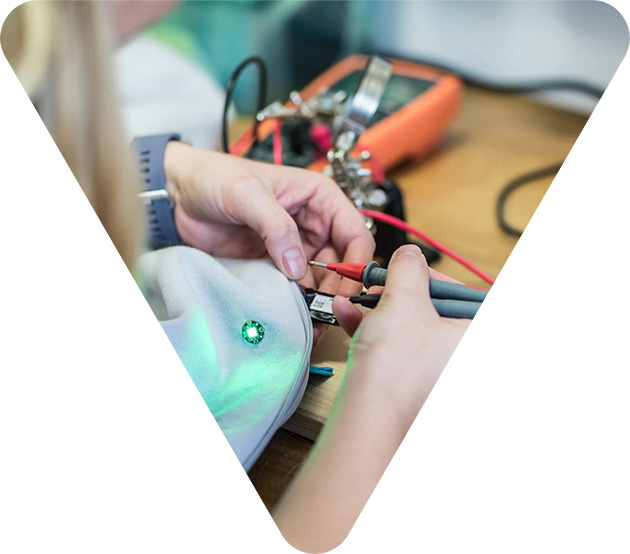

Though many tasks are being taken over by robots, this is also creating numerous new jobs and business ideas. In Dresden, for example, six young scientists from the start-up “Wandelbots” are working on a solution which could soon revolutionise companies’ production processes well beyond Saxony’s borders. The idea is to use smart clothing to teach robots sequences of human movement, so that they can then carry out tasks on their own. When a worker lifts his arm and grasps an object, the robot can immediately trace his movement: the data is transmitted to a software program via the person’s jacket and gloves. Within just a few minutes, the machine thus knows exactly what to do, and can also adjust rapidly to new requirements. Thanks to the Wandelbots, tasks which specialists and programmers until recently needed several days to achieve require very little time or expert knowledge. Science fiction? Not at all! Various companies from all over Germany are helping the Wandelbots start-up get their solution on the market as soon as possible. One Berlin investor is even investing a six-figure sum in the project. TU Dresden and the state of Saxony are also lending a hand to ensure that Saxony’s companies can soon benefit from the new technology. We visited the team and learned what was behind the project from one of its founders, Christian Piechnick.